Created in 1994, LFB develops, produces and markets blood plasma-derived medicinal products for the treatment of serious pathologies and rare diseases. Its clientele is mainly made up of health institutions. In order to reinforce France's industrial and health sovereignty in this field, LFB has decided to significantly increase its production capacity by launching the construction of a new production plant in Arras, in the North of France.

The PIERRE GUERIN teams (EQUANS group) have designed a tailor-made solution to meet this unprecedented challenge.

Key figures

Key figures

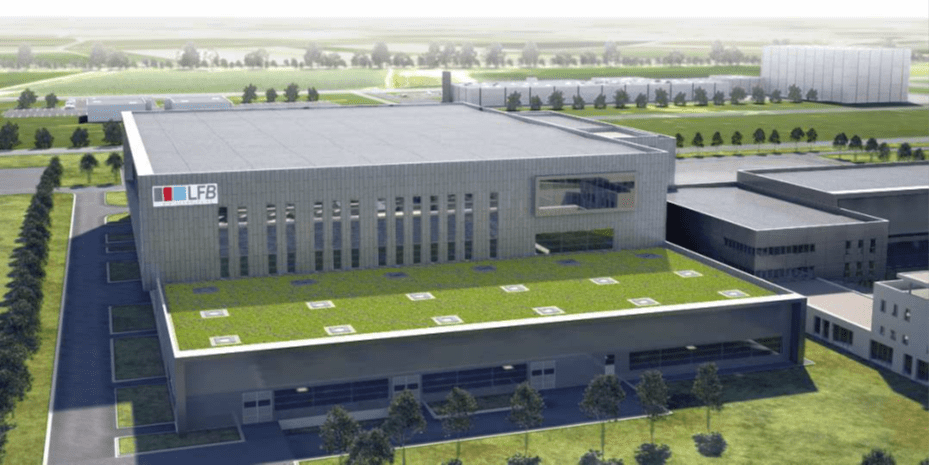

The pharmaceutical industry's biggest project in France

The Arras site is undoubtedly exceptional in its size, as far as the production of medicines in France is concerned: the future site will occupy no less than 6 hectares in the Actiparc business park, and its structure required the installation of 500 piles. The challenge also lies in the strict pharmaceutical standards governing the production of medicines, which require very high-tech equipment

PIERRE GUERIN (EQUANS group) has won the contract to design and supply 3 workshops dedicated to plasma thawing, albumin purification and immunoglobulin purification.

This future-oriented contract represents a real economic challenge as it will enable LFB to triple its drug production capacity to meet patients' needs and support the Group's international growth.